How Interposer Designs Simplify Mezzanine Connector Assembly

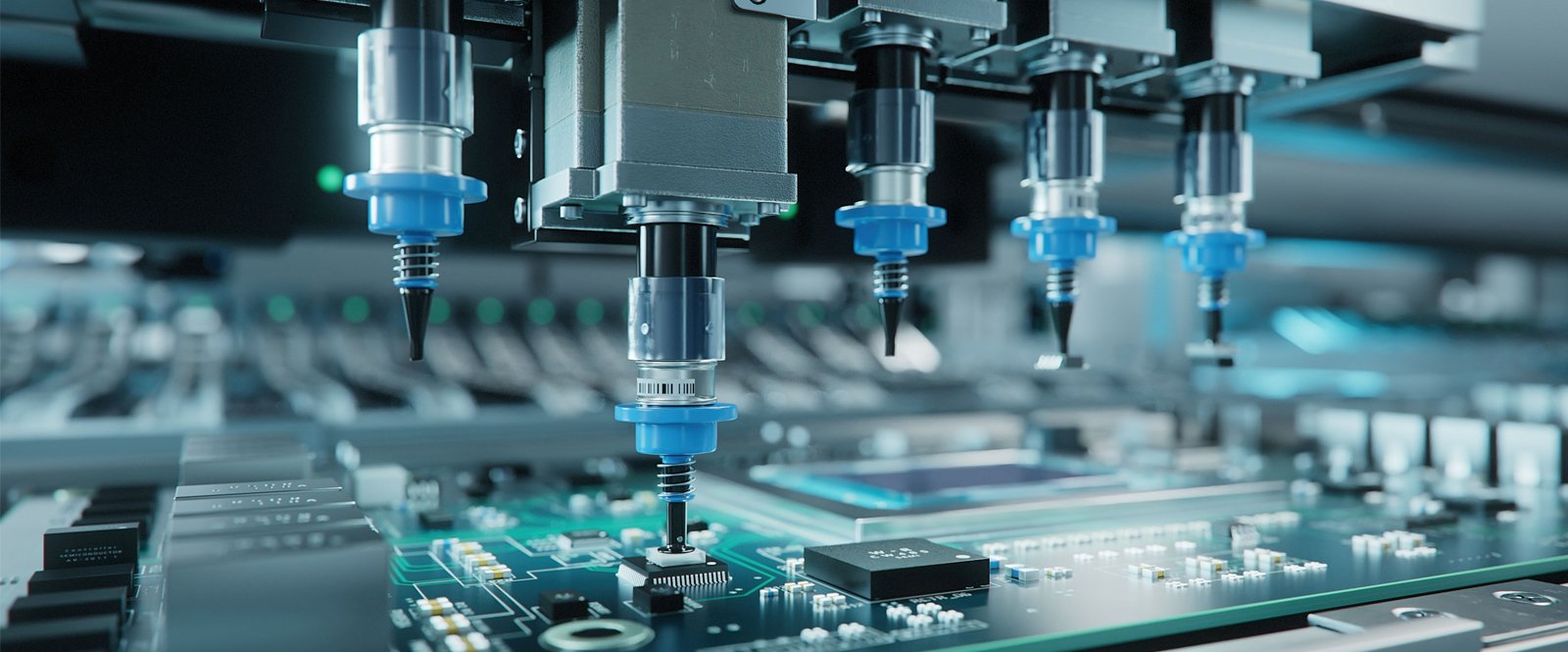

The evolution of pick-and-place technology spans decades, beginning in the 1960s with the emergence of surface-mount technology (SMT). Early machines were relatively simple—primarily used to place larger components like capacitors and resistors onto printed circuit boards (PCBs)—and could only place a few components per minute.

OPTIMIZING PICK-AND-PLACE ASSEMBLY WITH INTERPOSER MEZZANINE CONNECTORS

Today's advanced pick-and-place machines utilize robotic arms and machine vision to place miniature components with high speed and precision. For example, pick-and-place machines can place connectors with a precision of up to 0.00254 mm (1/10,000 inch), ensuring consistent placement and reducing defects—all while improving speed over manual assembly.

Uniform placement improves reliability, reduces costs, and enhances product consistency. These machines can be easily programmed to handle different connector types and layouts, making them adaptable to changing designs and high-mix manufacturing environments.

Connectors designed for pick-and-place are often packaged in reels or trays, making them suitable for high-volume automated assembly. Modern pick-and-place machines feature intuitive interfaces for simplified operation and programming. Design features like flat surfaces or kapton dots help vacuum nozzles securely grip the connector during placement. These features ensure that pick-and-place equipment can reliably handle connectors, integrating seamlessly into automated assembly processes and contributing to overall manufacturing efficiency.

SMT connectors designed for automated equipment include headers, I/O interfaces, and various coaxial, board-to-board, SMP, D-sub, and mezzanine types—all compatible with pick-and-place operations.

Interposer Designs

In recent years, many high-speed mezzanine connectors have adopted an interposer design—a compression-mounted interface often referred to in this context as an "interposer fit"—placed between two PCBs to facilitate high-speed signal transmission. This approach is commonly found in ball grid arrays (BGAs) or multichip modules and typically features a larger pitch for enhanced alignment and mechanical performance.

Interposer connectors play a critical role in mezzanine PCB designs. They offer flexible stacking heights that allow engineers to optimize board spacing without compromising electrical performance. Unlike traditional mezzanine connectors, interposer-based designs maintain high-speed signal transmission despite adding an additional contact point, ensuring reliable operation in compact and high-density applications.

Additionally, interposer connectors support low-mass, high-volume production, making them well-suited for automated assembly processes such as pick and place operations. By eliminating the need for complex cable harnesses or rigid stacking constraints, they simplify assembly, enhance durability, and improve overall system integration.

The Hirose Difference

Hirose's innovative interposer design offers significant advantages for high-speed BGA mezzanine applications, addressing key challenges in modern PCB assembly. Hirose mezzanine connectors feature a three-piece, low-mass design consisting of two compact components on the daughter card and motherboard, connected by an interposer. The low-mass structure of Hirose's connectors enhances pick and place capability, making it ideal for high-volume production while benefiting dual-sided PCB assemblies. By reducing the connector mass and simplifying the design, Hirose's interposer connectors enable:

- Better handling during automated assembly

- Reduced risk of components detaching during reflow soldering

- Improved coplanarity, minimizing assembly issues

- More efficient assembly of boards with components on both sides (dual-sided PCB assembly)

Enhanced Performance

Hirose's interposer design offers superior electrical performance via a special wafer in the interposer for crosstalk cancellation—this provides tight, controlled impedances throughout the connector profile, enabling higher frequencies with minimal impact on signal integrity. For example, the IT5 Series (25 Gbps) and IT8 Series (56 Gbps) offer a 1.0 mm BGA row pitch for high signal density. With the ability to transmit differential, single-ended, and power through one stackable package, the IT5 and IT8 Series can solve interface needs for both current and future designs.

Flexibility & Reliability

Utilizing a double-beam contact structure, Hirose interposer mezzanine connectors offer enhanced contact reliability via multiple points of contact. The dual-beam structure ensures a stable connection even under vibration or thermal stress. The beam design is incorporated into a floating structure, allowing for board misalignment absorption. This feature can accommodate ±0.2mm to ±0.8mm of misalignment in some models, simplifying pick and place mating and improving overall connection reliability in various applications.

With stacking heights ranging from 5mm to 46mm, Hirose's interposer connectors offer unmatched design flexibility to meet diverse application requirements.

Customization

OEMs can customize the interposer PCB in Hirose's connectors, such as the FX27 series, by integrating chip components, such as resistors, capacitors, or ICs, to enhance functionality to meet specific application requirements. This allows OEMs to embed signal conditioning or power management features directly into the interposer. By customizing the interposer with pre-installed components, OEMs can reduce assembly complexity and streamline production processes — this reduces the need for additional steps during board-level integration. In addition, the entire surface of the interposer PCB can be used as a conductor for power applications. This design improves heat dissipation efficiency and supports high current demands, making it ideal for applications requiring robust power.

The interposer PCB length can be adjusted to achieve various stacking heights (e.g., 22mm minimum for the FX27 series). This flexibility allows OEMs to tailor the connector to their specific mechanical and spatial constraints.

Conclusion

Hirose's interposer-driven connectors represent a significant advancement in mezzanine connector technology, outperforming competitors by optimizing for high-speed, high-reliability applications. Key differentiators include:

- Low-Mass Design: Reduces stress on PCBs, prevents component detachment during reflow, and ensures stable high-volume manufacturing.

- Exceptional Contact Reliability: The dual-beam structure enhances mechanical durability and electrical performance.

- Superior Signal Integrity: Crosstalk-reducing wafers and impedance-controlled profiles enable high-frequency operation with minimal loss.

- Unmatched Design Flexibility: Hirose interposers support a broad range of stacking heights, enabling customized PCB layouts without sacrificing performance.

By addressing key challenges in PCB assembly and offering superior electrical performance, these connectors provide a compelling solution for modern high-density, high-speed applications.

connection point

Welcome to 'Connection Point' - your go-to spot for the latest in electronics. Here, we're all about connecting you with fresh ideas, engaging stories, and innovative solutions from Hirose Electric. Whether you're a tech enthusiast or an industry professional, there's something here for everyone.

Don't miss out on any of our updates – subscribe now and join our community of innovators and thinkers.

Subscribe Here!

Subscribe Here!

For more information on how Hirose Electric's connectors can transform your wearable device design, visit hirose.com or contact our team of experts today.